sdavo

Registered

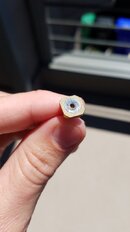

I am overhauling a Dacor 900 first stage, and I have been unable to find a source for a suitable new diaphragm. None of the diaphragms in the Trident catalog have the correct dimensions. Can the diaphragm pictured here be reused? It is still soft and pliable. Can the high pressure seat pictured be reused, or should I replace it?