stiebs

Contributor

Just got my new Halcyon Eclipse delivered this week, and in setting up the harness got enthused to sort out something which has always been on the todo list with doubles rig - replace those god awful wing nuts with something a bit more practical.

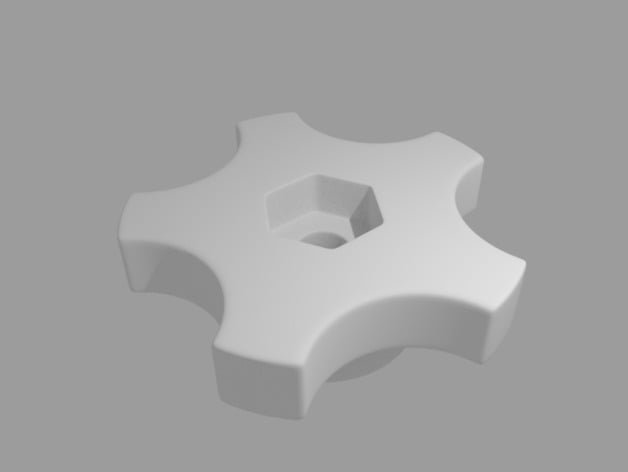

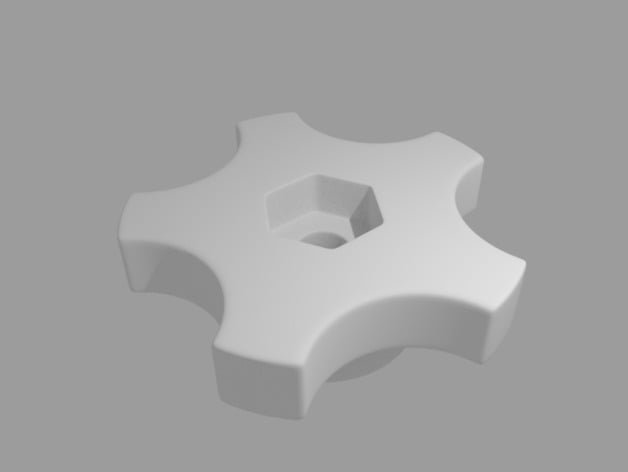

So went to thingiverse to see what I could find, and came up with this:

www.thingiverse.com

www.thingiverse.com

If anyone is interested, it's a pretty neat Blender model that has vertex groups to adjust the hole and hex sizes to suit with minimal fuss. I scaled the shape to 7x in x/y/z dimensions, then scaled HexSize and HexDepth to 0, and HoleSize to 3.

That resulted in a perfect size model to grip with fingers, and the hole is perfect to be tapped with a 5/16 UNC18 thread. I printed it with PLA at 100% fill - mainly because I wanted to make sure it was solid enough around the hole for tapping the thread.

So went to thingiverse to see what I could find, and came up with this:

PJS Hex Clamp Knob by pauljs75

Another clamping knob or thumbwheel thing. Scale and size as needed. The blender file has some shapekeys under vertex properties. They should make it easier to adjust the hex size, hex depth, and hole size. Has subdiv modifier, which should be applied before exporting if you want a smoother shape.

If anyone is interested, it's a pretty neat Blender model that has vertex groups to adjust the hole and hex sizes to suit with minimal fuss. I scaled the shape to 7x in x/y/z dimensions, then scaled HexSize and HexDepth to 0, and HoleSize to 3.

That resulted in a perfect size model to grip with fingers, and the hole is perfect to be tapped with a 5/16 UNC18 thread. I printed it with PLA at 100% fill - mainly because I wanted to make sure it was solid enough around the hole for tapping the thread.