The octo of one of my regsets is an Oceanic Alpha 7 with flex cover.

The original flex cover torn to pieces owing to age.

I replaced it with a generic flex cover. With time it also torn to pieces so I decided to 3D print a new one. The first try was with flex filament. The walls of the printed cover were too thick, so it resulted not so flexible.

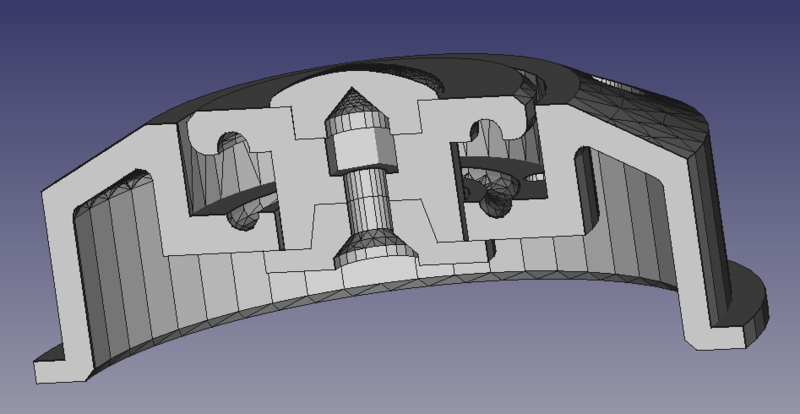

I could get a Stainless steel spring from an old BCD valve and decided to 3D print a cover with a button instead of a flex cover.

The cover fits as a flex cover, but it's rigid with a spring loaded button.

The whole set has 4 printed parts, the spring and a SS M4 screw and nut.

I've 3D printed it in ABS and I tested ok with a tank. Next try will be in the pool when this pandemic allow us to return to pools.

There are still some improvements I could do, but by the time it seems to work OK.

The original flex cover torn to pieces owing to age.

I replaced it with a generic flex cover. With time it also torn to pieces so I decided to 3D print a new one. The first try was with flex filament. The walls of the printed cover were too thick, so it resulted not so flexible.

I could get a Stainless steel spring from an old BCD valve and decided to 3D print a cover with a button instead of a flex cover.

The cover fits as a flex cover, but it's rigid with a spring loaded button.

The whole set has 4 printed parts, the spring and a SS M4 screw and nut.

I've 3D printed it in ABS and I tested ok with a tank. Next try will be in the pool when this pandemic allow us to return to pools.

There are still some improvements I could do, but by the time it seems to work OK.