Well, the idea that the single stage double hose regulator predates the two stage regulator is a common error. I guess some people think that it is a logical progression and they continue to spread that misconception, but it is wrong and well documented.

There are many pictures and descriptions of the early Cousteau double hose regulators (like the CG45) and then the ones sold in the US. The first Aqua Lung sold in the US was the Spaco around 1949 (basically the same design as the CG45). That was followed by the US Divers Aqua Lung from 1950 to 1954. All these regulators had two stages. The second stage was just a demand valve with no venturi flow assistance.

The history of the single hose regulators is also kind of interesting and some of the dates are not as well documented.

One of the early US made single hose regulator has mostly being forgotten. It was the Rose Aviation and it came out in 1956. It is a side breather with a smaller diaphragm (bellows style) than the Poseidon Cyklon. I don’t know how well they worked. I actually have two of them, but I have never had time to look into them.

I have read that Emile Gagnan actually had one of the earliest designs for a single hose regulator, but Spirotechnique/ US Divers and the Cousteau group liked the looks of the double hose and therefore the first US Divers single hose was not in the market until relatively late.

The Scott Hydro-Pak was another single hose regulator competing against the Aqua Lung. The same company that makes the Scott Air-Pak SCBA still in use today for fire fighting and other industrial contaminated air applications.

Scott Aviation Corporation of Lancaster, New York, was founded by Earle M. Scott in 1932. The civilian version of the Hydro-Pak was around from 1953 to about 1962, also predating the Cyklon and maybe even the Porpoise (but that is another debate).

The Scott Hydro-Pak included a full-face mask and the tank was worn with the valve on the bottom for easy access (like most SCBA). They were a bit expensive and lost market to the Aqua Lung. It would have interesting if they would have been more popular, the full face mask might have become much more popular and we all may be using cylinders with the valves on the bottom.

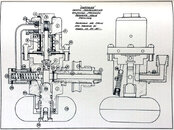

Here is information on the Scott Hydro-Pak

Double Hose Regulators - Scott

There are many pictures and descriptions of the early Cousteau double hose regulators (like the CG45) and then the ones sold in the US. The first Aqua Lung sold in the US was the Spaco around 1949 (basically the same design as the CG45). That was followed by the US Divers Aqua Lung from 1950 to 1954. All these regulators had two stages. The second stage was just a demand valve with no venturi flow assistance.

The history of the single hose regulators is also kind of interesting and some of the dates are not as well documented.

One of the early US made single hose regulator has mostly being forgotten. It was the Rose Aviation and it came out in 1956. It is a side breather with a smaller diaphragm (bellows style) than the Poseidon Cyklon. I don’t know how well they worked. I actually have two of them, but I have never had time to look into them.

I have read that Emile Gagnan actually had one of the earliest designs for a single hose regulator, but Spirotechnique/ US Divers and the Cousteau group liked the looks of the double hose and therefore the first US Divers single hose was not in the market until relatively late.

The Scott Hydro-Pak was another single hose regulator competing against the Aqua Lung. The same company that makes the Scott Air-Pak SCBA still in use today for fire fighting and other industrial contaminated air applications.

Scott Aviation Corporation of Lancaster, New York, was founded by Earle M. Scott in 1932. The civilian version of the Hydro-Pak was around from 1953 to about 1962, also predating the Cyklon and maybe even the Porpoise (but that is another debate).

The Scott Hydro-Pak included a full-face mask and the tank was worn with the valve on the bottom for easy access (like most SCBA). They were a bit expensive and lost market to the Aqua Lung. It would have interesting if they would have been more popular, the full face mask might have become much more popular and we all may be using cylinders with the valves on the bottom.

Here is information on the Scott Hydro-Pak

Double Hose Regulators - Scott