I don’t know what does the first stage seat has to do with the exhaust hose, or why did you posted that in this thread. In any case, I am actually seeing two different things on the pictures of that seat. The indentation from the volcano and a crack on the surface of the seat material. It is just a picture, so please let me know If what I see from the picture is not correct.

I am pointing to the indentation from the volcano orifice with a red arrow and to the crack with a green arrow.

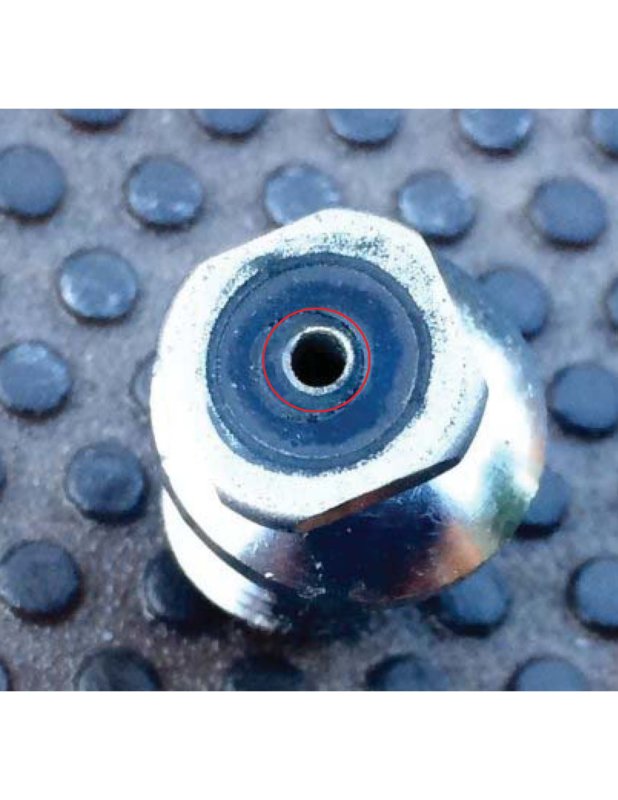

I also added a red circle on top of the indentation from the volcano orifice. You may notice that the crack doesn’t for a good circle. It doesn’t even has a smooth curve.

This crack is definitely a defect or a malfunction. Again I do not know where Bryan gets his seats other that they are being made by a Scuba parts manufacturer/ supplier. I have seen bad seats before.

The red circle is covering volcano orifice indentation:

If you are unhappy with your Argonaut, you should contact Bryan. He will probably give your money back, but I can’t speak for him.

I am pointing to the indentation from the volcano orifice with a red arrow and to the crack with a green arrow.

I also added a red circle on top of the indentation from the volcano orifice. You may notice that the crack doesn’t for a good circle. It doesn’t even has a smooth curve.

This crack is definitely a defect or a malfunction. Again I do not know where Bryan gets his seats other that they are being made by a Scuba parts manufacturer/ supplier. I have seen bad seats before.

The red circle is covering volcano orifice indentation:

If you are unhappy with your Argonaut, you should contact Bryan. He will probably give your money back, but I can’t speak for him.