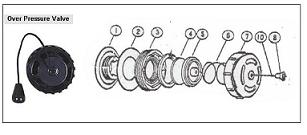

I have a Dive Rite smb with an overpressure/dump valve. The valve has 3 pieces that screw together; the bottom 2 pieces/rings screw together form a seal on the sausage opening and the upper piece houses the spring and seal.

After completely cleaning and reassembling for the first time it seems if the top section is twisted all the way down (tight) the spring fully compresses and the dump function is disabled. If I leave the upper ring loose, the dump is functional. But, the system is not snugged up tight and so it doesn't seem right. I know, I should have paid closer attention when I took it all apart... did I lose a spacer? Does anyone have any pointers?

After completely cleaning and reassembling for the first time it seems if the top section is twisted all the way down (tight) the spring fully compresses and the dump function is disabled. If I leave the upper ring loose, the dump is functional. But, the system is not snugged up tight and so it doesn't seem right. I know, I should have paid closer attention when I took it all apart... did I lose a spacer? Does anyone have any pointers?